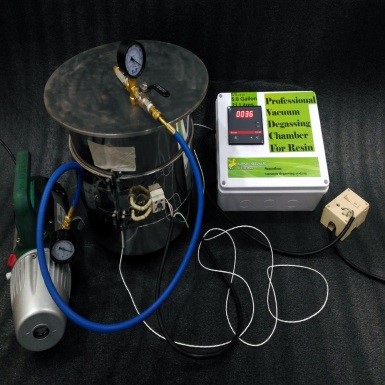

Burhani Vacuum oven is provided with digital electronic control,

built-in over-temperature protection, and a fully flexible vacuum/purge/release

system for a range of applications including those that require elevated

temperature in reduced atmosphere.

These heated vacuum oven Chamber provide precise and fast

heating and heat transfer which helps minimize operation time. These vacuum

ovens are compliant with the highest level of requirements for heating

applications under a vacuum. LED display of actual and set point

temperature. Temperature Range available

as per customer requirements. Digital microprocessor control

Product

Features of the Heated Vacuum Oven

—Stainless steel chamber for long-term air-tightness

performance.

—Heavy Duty Industrial Heating System

—Adjustable Digital Temperature display and Controller

—Various Temperature Ranges available on request

—Burhani Vacuum chamber has a rounded edge at the top, for the

protection of silicone gasket.

—Vacuum gauge is assembled on a separate port, so that the

reading remains accurate even while pumping/venting the chamber.

—Gauge reading in both in Hg and Mpa.

—All kits are vacuum tested for 24 hours before packaging.

(leakage less than 2.0 inHg at 24 hours)

—Two-sided flappable vacuum gasket for better durability and

reliability.

—The gasket is chemically resistant to butane and other

solvents.

— Stainless Steel lid for long life .

—Strong elastic food grade silicone vacuum hose can

connect/disconnect easily with the pump/chamber.

—50um air filter on the vent valve to reduce air flow and

prevent any dust/powder flowing into the chamber.

—Easy to install and low-cost to maintain: the chamber can be

assembled in 5 minutes.

—45 day complimentary warranty and life-long parts support.

—

—Product Specs & Part List of the Chamber

—Vacuum Chamber: stainless steel

—Lid: Stainless Steel

—Controller : Microprocessor based

Digital Temperature controller

—Vacuum Gasket: silicone, resistant to

Butane and other solvents.

—Vacuum Gauge Assembly: 0.5 inHg accuracy.

—Valve Assembly: very high quality

air-tight brass valves, with 50um filter on vent port

—Vacuum Hose: 3.3' / 1 meter food

grade collapse-proof silicone hose, 3mm wall thickness (8mm I.D, 14mm O.D)

—Vacuum Pump Adapter: 3/8“ hose barb to 1/4

SAE flare port.

DOWNLOAD CATALOG

visit at: https://bhfvacuum.com/

Heated Vacuum Oven with Pump

ReplyDeleteStrong elastic food grade silicone vacuum hose can connect/disconnect easily with the pump/chamber.

ReplyDeletehttps://bhfvacuum.com/heated-vacuum-degassing-chamber.html

mperature Range available as per customer requirements. Digital microprocessor control

ReplyDeleteHeated Vacuum Oven with Pump

Vacuum Degassing Chamber Vacuum degassing is the process of using vacuum to remove gases from compounds which become entrapp.

ReplyDeleteVacuum degassing chamber manufactured by BHFTECH Burhani Engineering Technology is a vacuum system comprising of Vacuum chamber and vacuum pump that pulls 29 inches of mercury is used to remove the air from high viscosity materials like epoxy resin, Liquid silicone rubber, liquid plastic and Polyurethane rubber to make bubble free casting. BHFTECH is the only exporter and manufacturer of resin vacuum degasser chamber in India for degassing silicone.

ReplyDeleteanufactured by Burhani Engineering Technology is a vacuum system comprising of Vacuum chamber and vacuum pump that pulls 29 inches of mercury is used to remove the air from high viscosity materials like epoxy resin, Liquid silicone rubber, liquid plastic and Polyurethane rubber to make bubble free casting. Burhani Engineering Technology is the only exporter and manufacturer of resin vacuum degasser chamber in India for degassing silicone.

Delete